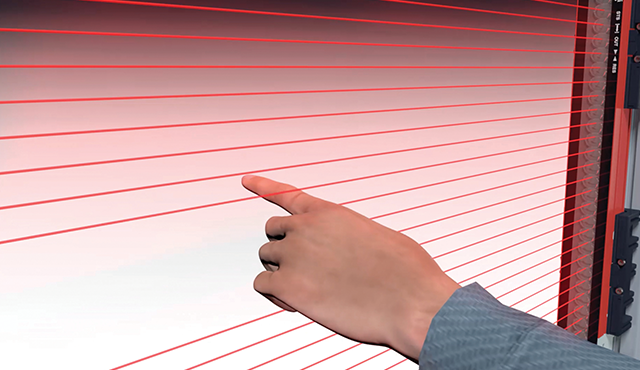

The most misapplied safety devices in the industry are light curtains and laser scanners, common issues with installations include:

- Application not suitable for light curtain/scanner, eg; the machine ejects parts, the machine has a long stopping time, environmental influences

- Light curtain placed too close to the hazard – Insufficient safety distance

- Scanner safety field size is too small – Insufficient safety distance

- Stopping performance monitoring not provided when it should be

- Muting sensors not mounted correctly

Guidance is now at hand with the new standard AS 4024.2802:2017 being introduced. This standard provides information on all aspects of designing/installing presence sensing system such as light curtains and laser scanners.

AS 4024.2802:2017 covers safety distance calculation to address issues 2 and 3 in the above list, but it does a lot more as well.

It also provides an explanation of how to ensure the application is suitable for presence sensing devices, this guidance can help address issue 1 from the above list.

Issue 5 a major problem in the industry, it is common to see muting sensors mounted incorrectly and this increases the risk of operators inadvertently muting the light curtain and being exposed to hazards. AS 4024.2802:2017 has information on all common muting configurations and provides clear instructions on how the sensors are mounted and the timing sequence of the muting operation.

Issue 4 reflects the fact that many designers/installers aren’t aware of the requirement of stopping performance monitoring. If the light curtain/scanner is used as a trip device then the safety distance is integral to ensure the risk is controlled. If the machine’s stopping time is subject to deterioration (eg: brake wear) then the stopping time of the machine should be monitored. This information can be used to schedule preventative maintenance to ensure the safety risk is controlled and reduce unexpected downtime.

If you design/install or maintain presence sensing systems, such as light curtains or laser scanners, I recommend referencing the new AS 4024.2802:2017 standard.